RFID Tracking: RFID Tracking for Retail Stores

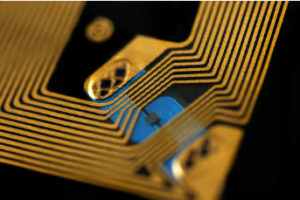

RFID tracking enables businesses to monitor items as they move throughout their supply chains and retail stores, thanks to tiny tags attached to items that transmit radio waves back to RFID readers.

RFID tags offer businesses an effective solution for inventorying assets 15-20 times faster than manual or barcode processes.

Real-time Inventory Visibility

RFID’s most significant advantage lies in its automatic tracking of each item as it moves throughout your supply chain, from vendor warehouses and satellite sites through 3PLs, gate-in/gate-out locations, trailers, trucks, and shipping containers – each movement is tracked with real-time inventory accuracy.

RFID’s most significant advantage lies in its automatic tracking of each item as it moves throughout your supply chain, from vendor warehouses and satellite sites through 3PLs, gate-in/gate-out locations, trailers, trucks, and shipping containers – each movement is tracked with real-time inventory accuracy.

Automating data-driven processes eliminates human scanning errors and logging mistakes while increasing productivity by decreasing the time required for manual scanning and logging processes.

Tracking inventory with RFID allows for improved production flow analytics, eliminating bottlenecks and speeding up product delivery times. Furthermore, RFID helps cut costs by instantly checking in entire shipments at once and auto-reordering when safety stock levels hit – helping prevent expensive overstocking! Moreover, this technology improves in-store operations for buy online/pick up in-store (BOPIS) customers by giving visibility on store floors so staff can locate items more quickly, ultimately leading to improved customer experience and increased sales.

Increased Product Lifespan

Real-time inventory tracking is vital to offering buy online and pick up in-store (BOPIS). But for retailers seeking to innovate and distinguish themselves from the competition, RFID tracking has become more than simply an inventory management solution.

Employing RFID tracking systems allows retailers to pinpoint the precise location of products stored within their warehouse, right down to which rack or shelf they’re on. That enables retailers to maximise inventory turns while improving customer experiences by minimising out-of-stock situations and providing more precise data regarding product availability.

RFID also offers additional advantages beyond inventory management, including theft prevention by creating a transparent chain of custody for expensive equipment such as forklifts or IT assets, improving health and safety by restricting their use after failing inspection, tracking employee movements across a warehouse floor for efficient utilisation and loss prevention purposes, as well as tracking employee movement on its premises for improved loss prevention purposes.

Enhanced Security

Lost, misplaced, or stolen assets represent a severe drain on most asset-heavy industries. These risks take an enormous toll on profitability, from auto manufacturers’ reusable packaging costing them $750 million annually to construction site theft costing them $1 billion each year.

RFID tracking provides complete transparency into your assets to protect yourself against these costly risks. Unlike barcodes that must be read directly before them, RFID tags are automatically identified and scanned as they move between facilities, eliminating manual scanning costs and decreasing labour expenses and errors.

RFID tracking enables your facility to set virtual perimeters and notify security when personnel or equipment enter these boundaries, simplify maintenance by providing accurate histories and schedules of each asset, resulting in reduced downtime and enhanced productivity, capture video footage of shoplifting incidents for prosecution by law enforcement agencies and build strong cases against perpetrators using video footage captured through RFID tracking, as well as build strong cases against them using this data.

Increased Productivity

Businesses often waste time and effort manually tracking inventory data logging procedures and inventory control processes, which can be time-consuming and prone to human errors. By automating these functions, businesses can increase productivity.

With RFID, workers can focus on more valuable tasks. For instance, they can quickly compile an inventory list by scanning items that have been tagged and significantly decrease labour costs while increasing accuracy when physical inventory counts are performed.

As retailers embrace omnichannel and shift associate priorities, they are also finding new ways to use RFID to improve operational efficiency. Modern RFID solutions reset store economics by boosting productivity, cutting costs, and increasing revenue. Using advanced software and sensors, RFID can accurately locate and track products in warehouses, stores, and at the consumer-facing level—while providing visibility to shoppers and associates.